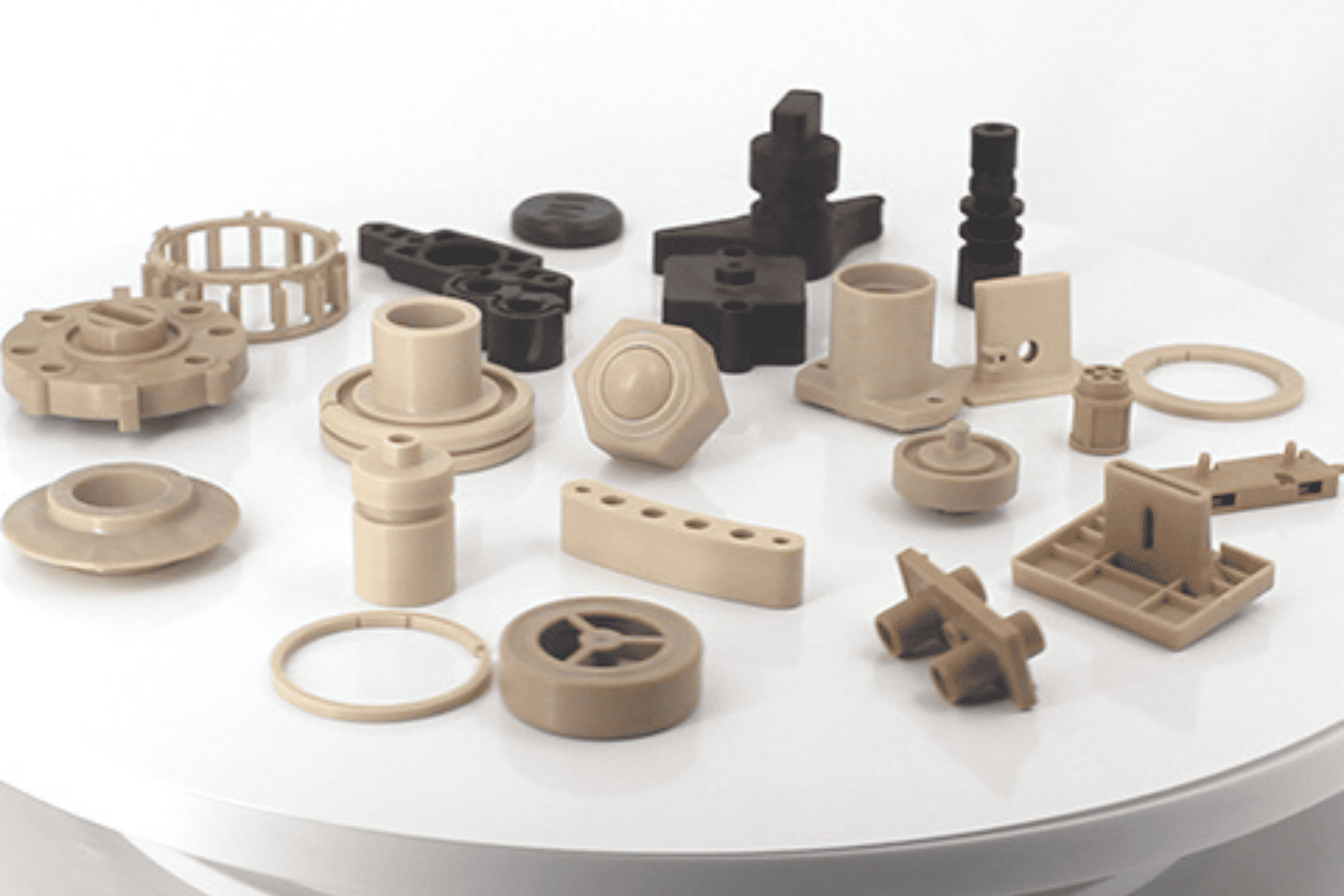

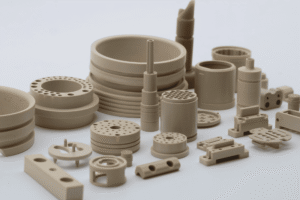

Introduction Turning a block of high-performance polymer into a precision component requires technical expertise and top-tier infrastructure. At Polymat India, we specialize in machining engineering plastics to exact client specifications.

Step-by-Step Process

- Material Selection: Based on mechanical, thermal, and chemical requirements

- Stock Shape Preparation: Cut to size from rods, blocks, or plates

- CNC Machining: High-precision turning, milling, and drilling

- Quality Inspection: Ultrasonic flaw detection, dimensional verification

- Finishing: Surface finishing or secondary processing if required

Why Choose Polymat’s Machining Services?

- ISO 9001:2015 certified processes

- Advanced machines with tight tolerances

- Skilled operators & engineering support

- In-house stock shape inventory

Conclusion Polymat ensures your final component is not just accurate, but reliable under performance stress.

CTA: Upload your component design and experience precision manufacturing.